The material selection of the CB antenna (Citizen's Band Antenna) has a crucial impact on its durability and signal quality. Here is a detailed analys...

READ MORE- Home

- About Us

- Product

- Vehicle Mobile Antenna

- TRUCK&CARAVAN TV (470Mhz-862Mhz) Antenna

- TRUCK&CARAVAN CB(26Mhz-29Mhz) Antenna

- TRUCK&CARAVAN VHF/UHF(144/430Mhz, 477Mhz) Antenna

- TRUCK&CARAVAN FM/AM DAB (174Mhz-230Mhz)(88-108MHZ) Antenna

- TRUCK&CARAVAN HF(3Mhz-30Mhz) Antenna

- TRUCK&CARAVAN 3G 4G 5G(690Mhz-3.8G) Antenna

- TRUCK&CARAVAN GPS(1575.42±3Mhz) Antenna

- Marine Antenna

- Base&Home Antenna

- RF Coaxial Cable & RF Connector

- Antenna Accessory

- Vehicle Mobile Antenna

- Customized Product

- Contact Us

- Home

- About Us

- Product

- Vehicle Mobile Antenna

- TRUCK&CARAVAN TV (470Mhz-862Mhz) Antenna

- TRUCK&CARAVAN CB(26Mhz-29Mhz) Antenna

- TRUCK&CARAVAN VHF/UHF(144/430Mhz, 477Mhz) Antenna

- TRUCK&CARAVAN FM/AM DAB (174Mhz-230Mhz)(88-108MHZ) Antenna

- TRUCK&CARAVAN HF(3Mhz-30Mhz) Antenna

- TRUCK&CARAVAN 3G 4G 5G(690Mhz-3.8G) Antenna

- TRUCK&CARAVAN GPS(1575.42±3Mhz) Antenna

- Marine Antenna

- Base&Home Antenna

- RF Coaxial Cable & RF Connector

- Antenna Accessory

- Vehicle Mobile Antenna

- Customized Product

- Contact Us

Web Menu

- Home

- About Us

- Product

- Vehicle Mobile Antenna

- TRUCK&CARAVAN TV (470Mhz-862Mhz) Antenna

- TRUCK&CARAVAN CB(26Mhz-29Mhz) Antenna

- TRUCK&CARAVAN VHF/UHF(144/430Mhz, 477Mhz) Antenna

- TRUCK&CARAVAN FM/AM DAB (174Mhz-230Mhz)(88-108MHZ) Antenna

- TRUCK&CARAVAN HF(3Mhz-30Mhz) Antenna

- TRUCK&CARAVAN 3G 4G 5G(690Mhz-3.8G) Antenna

- TRUCK&CARAVAN GPS(1575.42±3Mhz) Antenna

- Marine Antenna

- Base&Home Antenna

- RF Coaxial Cable & RF Connector

- Antenna Accessory

- Vehicle Mobile Antenna

- Customized Product

- Contact Us

Product Search

Exit Menu

- Vehicle Mobile Antenna

- TRUCK&CARAVAN TV (470Mhz-862Mhz) Antenna

- TRUCK&CARAVAN CB(26Mhz-29Mhz) Antenna

- TRUCK&CARAVAN VHF/UHF(144/430Mhz, 477Mhz) Antenna

- TRUCK&CARAVAN FM/AM DAB (174Mhz-230Mhz)(88-108MHZ) Antenna

- TRUCK&CARAVAN HF(3Mhz-30Mhz) Antenna

- TRUCK&CARAVAN 3G 4G 5G(690Mhz-3.8G) Antenna

- TRUCK&CARAVAN GPS(1575.42±3Mhz) Antenna

- TRUCK&CARAVAN TV (470Mhz-862Mhz) Antenna

- Marine Antenna

- Base&Home Antenna

- RF Coaxial Cable & RF Connector

- Antenna Accessory

Categories

- Vehicle Mobile Antenna

- TRUCK&CARAVAN TV (470Mhz-862Mhz) Antenna

- TRUCK&CARAVAN CB(26Mhz-29Mhz) Antenna

- TRUCK&CARAVAN VHF/UHF(144/430Mhz, 477Mhz) Antenna

- TRUCK&CARAVAN FM/AM DAB (174Mhz-230Mhz)(88-108MHZ) Antenna

- TRUCK&CARAVAN HF(3Mhz-30Mhz) Antenna

- TRUCK&CARAVAN 3G 4G 5G(690Mhz-3.8G) Antenna

- TRUCK&CARAVAN GPS(1575.42±3Mhz) Antenna

- Marine Antenna

- Base&Home Antenna

- RF Coaxial Cable & RF Connector

- Antenna Accessory

Recommended Products

Contact Us

Marine HF(3Mhz-30Mhz) Antenna Supplier

-

HF-006 HF Multi-band High Frequency Communication Antenna

Band: 80,40,20,15, 10mts. Center frequency: 3.56, 7.05, 14.2, 21.1, 29MHz Connector: PL-259, 3/8-24 Impedance: 50ohm Whip Length: adjusted Material: C...

-

HF-009 Eight-band Adjustable Communication HF Antenna

Band: 80,40,30,20,17,15,10,6mts. Center frequency: 3.56, 7.05, 10.1, 14.2, 18, 21.1, 29, 50MHz Connector: UHF MALE(PL-259) Impedance: 50ohm Whip Lengt...

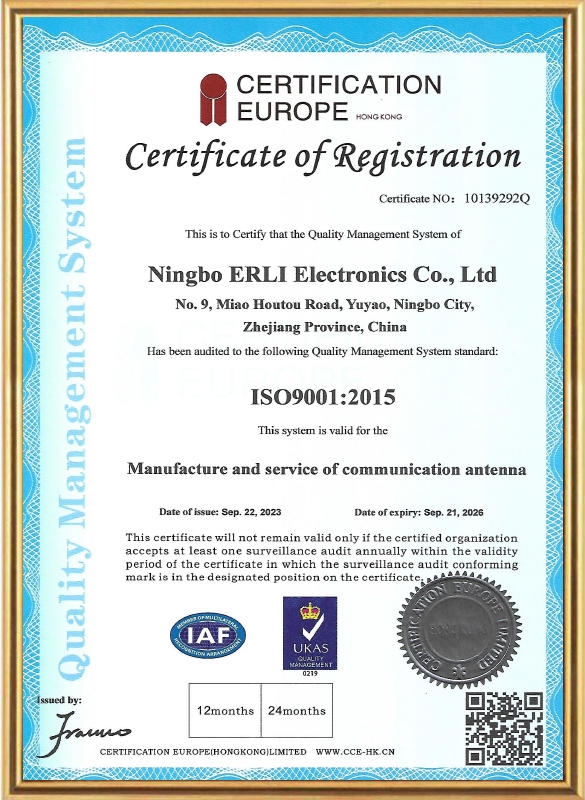

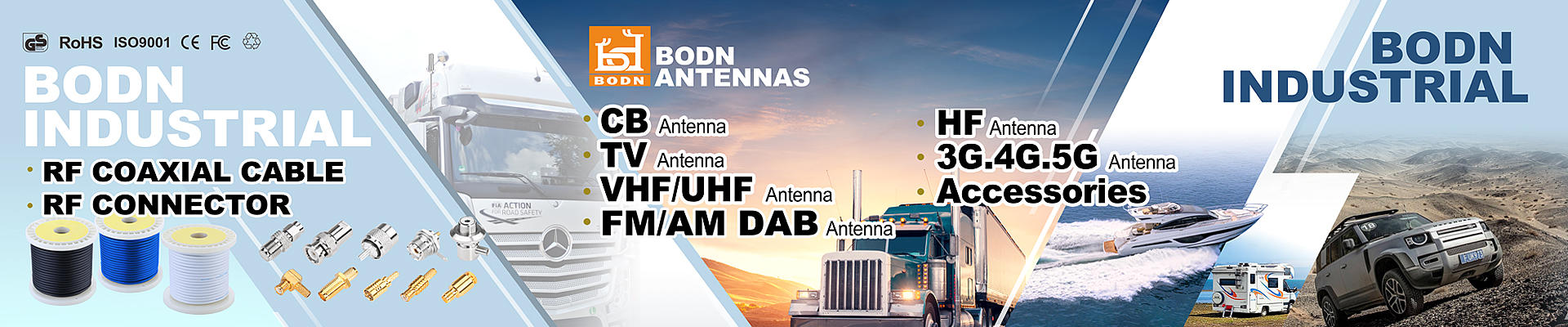

The company has a professional technical development team and high-precision testing instruments and equipment: German Rohde Schwarz network analyzers, spectrum analyzers, handheld high-precision wave rejection ratio meters, signal transmitters, and microwave test shielded chambers. Mechanical testing equipment includes high temperature +150 degrees, low temperature -60 degrees test chambers, anti-UV aging test chambers, tensile testers, salt spray testing machines, etc. Our products mainly include(Marine antennas),TV/DVB-T antennas, CB antennas, VHF and UHF antennas, FM/AM DAB car antennas, mobile phone LTE, 3G, 4G, 5G and other antenna accessories.

-

-

In a multipath interference environment, optimizing the reception performance of a CB Antenna (circularly polarized antenna) is a complex but crucial ...

READ MORE -

The radiation pattern of a CB antenna (Citizen's Band Antenna) has a significant impact on its communication range. Radiation pattern describes the ab...

READ MORE -

Evaluating the performance of a CB antenna (Citizen's Band Antenna) under different terrain and climate conditions is a complex process that requires ...

READ MORE

The installation and calibration of the Marine HF Antenna on offshore mobile platforms does have some special requirements, which are designed to ensure that the antenna can maintain efficient and stable communication performance in the complex and ever-changing marine environment. Here are some key special requirements and their associated details:

1. Stability requirements

Mobile offshore platforms, such as large cargo ships, oil tankers or warships, often face the test of strong winds and waves. These harsh conditions can cause significant platform sway and vibration. Therefore, the installation of the Marine HF Antenna must take these factors into account to ensure that it remains stable even in extreme weather conditions.

Mounting bracket design: Brackets are usually made of high-strength, corrosion-resistant materials, such as stainless steel or special alloys. Their design takes into account the dynamic characteristics of the platform, including rocking and vibration amplitudes, to ensure that the antenna remains vertical and stable in a variety of conditions.

Fixings and fastenings: Fixings including bolts, nuts and washers are carefully selected and tested to ensure they can withstand the high humidity, salt spray and corrosion found in marine environments. During the installation process, these fixtures must be tightened in strict accordance with the specifications, and tools such as torque wrenches are used to ensure that each tightening point reaches the specified torque.

2. Height and location selection

The mounting height and location of the antenna are critical to its performance. On an offshore mobile platform, selecting a suitable installation location is a complex task that requires the consideration of multiple factors.

Avoid metal interference: Large metal structures on the platform, such as masts, radomes, etc., may interfere with the performance of the antenna. Therefore, during the installation process, professional electromagnetic simulation software or field testing needs to be used to determine the best installation location to reduce these interferences.

Field of view and communication target: The antenna should be installed in a position to ensure that it has a wide field of view in order to establish a connection with distant communication targets. This usually means mounting the antenna high on the platform, such as the top of a mast or on the deck at the stern of a ship.

3. Directional adjustment

Marine HF Antenna is often directional and requires precise adjustment of its pointing to maximize communications. This often involves complex measurement and adjustment processes.

Use a compass: During the early stages of installation, a high-quality compass can be used to determine the initial direction of the antenna. However, due to the dynamic nature of offshore platforms, precise direction may not be obtained with a compass alone.

Professional measuring equipment: In order to obtain more precise directional adjustment, professional measuring equipment can be used, such as a signal analyzer or spectrum analyzer. These devices measure the antenna's radiation pattern and signal strength and make fine adjustments accordingly.

4. Electrical connection and grounding

Proper electrical connections and grounding are key to ensuring stable antenna performance. On mobile offshore platforms, these factors are particularly important.

Coaxial cable selection: Coaxial cable selection requires consideration of its impedance, attenuation, and shielding properties. In marine environments, cables must also have excellent waterproof and corrosion resistance.

Waterproof sealing: All cable connections must be strictly watertight sealed to prevent seawater from penetrating and causing electrical failure. This usually involves using materials such as specialized waterproof tape, sealant or heat shrink tubing.

Grounding System: A grounding system is key to preventing electrical noise and interference. On offshore platforms, grounding systems need to be specially designed to ensure they can withstand the high humidity and corrosion found in the marine environment. In addition, the measurement and adjustment of ground resistance are also important steps to ensure the grounding effect.

5. Calibration and testing

Once installed, the Marine HF Antenna must be calibrated and tested to ensure it performs as expected. This often involves a complex series of steps and specialized testing equipment.

Transmit power and receive sensitivity test: Use professional test equipment to measure the transmit power and receive sensitivity of the antenna to ensure that it meets communication requirements. These tests are typically performed in a laboratory or field setting.

Frequency response test: By testing the performance of the antenna in different frequency bands, you can understand its communication capabilities under different conditions. This helps determine the antenna's operating range and optimize its performance.

Tuning and Optimization: Depending on the test results, the antenna may need to be fine-tuned or optimized to improve its performance or resolve potential issues. This may require multiple iterations and testing until satisfactory results are achieved.

6. Consider future expansion and upgrades

As communication technology continues to advance and ship communication needs grow, antenna systems may need to be upgraded or expanded in the future. Therefore, future expansion should be fully considered when installing.

Reserve interfaces and space: During the installation process, enough interfaces and space should be reserved so that new antennas or existing equipment can be easily added in the future.

Compatibility considerations: When selecting antennas and related equipment, communication standards and protocols that may be used in the future should be taken into account to ensure that they have good compatibility and interoperability.

Following these special requirements and paying attention to details can ensure that Marine HF Antenna achieves efficient and stable communication performance on offshore mobile platforms, providing a strong guarantee for the ship's navigation safety and smooth communication.

- Home

- About Us

- Product

- Vehicle Mobile Antenna

- TRUCK&CARAVAN TV (470Mhz-862Mhz) Antenna

- TRUCK&CARAVAN CB(26Mhz-29Mhz) Antenna

- TRUCK&CARAVAN VHF/UHF(144/430Mhz, 477Mhz) Antenna

- TRUCK&CARAVAN FM/AM DAB (174Mhz-230Mhz)(88-108MHZ) Antenna

- TRUCK&CARAVAN HF(3Mhz-30Mhz) Antenna

- TRUCK&CARAVAN 3G 4G 5G(690Mhz-3.8G) Antenna

- TRUCK&CARAVAN GPS(1575.42±3Mhz) Antenna

- Marine Antenna

- Base&Home Antenna

- RF Coaxial Cable & RF Connector

- Antenna Accessory

- Vehicle Mobile Antenna

- Customized Product

- Contact Us

- How does the CB Antenna's material selection affect its durability and signal quality?

- How to optimize the reception performance of CB Antenna in a multi-path interference environment?

- How does the CB Antenna's radiation pattern affect its communication range?

- How to evaluate the performance of CB Antenna in different terrain and climate conditions?

- How should the optimal size of CB Antenna be determined under different frequency bands?

Free Consultation

Copyright © Shanghai Bodn Industrial Co., Ltd. All rights reserved.Wholesale Marine HF(3Mhz-30Mhz) Antenna Supplier

English

English Español

Español